- What Exactly Is an Air Leak in a Suction Line?

- The Silent Saboteurs: Symptoms of an Air Leak in Suction Line

- Pinpointing the Problem: Common Causes of Air Leaks

- Diagnostic Dilemma: How to Detect an Air Leak in Your Suction Line

- The Crucial Fix: Solving the Air Leak Problem

- Why Professional Intervention Matters

- Conclusion

Air Leak in Suction Line is a common yet critical issue that can plague a variety of mechanical systems, from refrigerators and air conditioners to water pumps and industrial machinery. This seemingly small fault can lead to significant reductions in efficiency, increased energy consumption, system damage, and even complete operational failure if left unaddressed. Understanding the intricacies of an air leak in a suction line, its tell-tale signs, causes, and most importantly, the crucial fixes involved, is paramount for anyone managing or operating such systems.

What Exactly Is an Air Leak in a Suction Line?

A suction line is designed to draw fluid (liquid or gas) from one point to another, typically towards a compressor or pump. It operates under negative pressure – a vacuum or partial vacuum – relative to the ambient atmosphere. When there’s a breach in this line, even a minuscule one, the external atmospheric pressure will force air into the system. This ingress of air, instead of the intended fluid, can wreak havoc. In refrigeration and HVAC systems, it introduces non-condensable gases into the refrigerant circuit. In water pumps, it can cause a loss of prime or cavitation. In hydraulic systems, it introduces bubbles into the fluid, affecting performance and potentially damaging components.

The Silent Saboteurs: Symptoms of an Air Leak in Suction Line

Identifying an air leak can sometimes be challenging, as its symptoms can mimic other problems. However, several common indicators can point to an air leak in suction line:

Reduced Performance and Efficiency: The most noticeable symptom. A refrigerator might not cool effectively, an AC unit struggles to maintain temperature, or a pump delivers less flow. This is because the system is dealing with air instead of efficiently moving the intended fluid.

Unusual Noises: Gurgling, hissing, or bubbling sounds, particularly near the intake or pump, strongly suggest air entering the line.

Short Cycling: In refrigeration and HVAC, the compressor might repeatedly turn on and off due to difficulty in achieving the set temperature or pressure, leading to excessive wear and tear.

System Overheating: When a system works harder to compensate for air ingress, it generates more heat, which can lead to component damage.

Loss of Prime (Pumps): Water pumps reliant on suction might fail to draw water entirely or lose their prime frequently.

High Energy Bills: An inefficient system with an air leak will consume more power to do the same job, translating into higher utility costs.

Visual Cues (Refrigeration/HVAC): Bubbles in a liquid line sight glass (when they shouldn’t be there) or unusual frosting patterns on the suction line itself can be strong indicators.

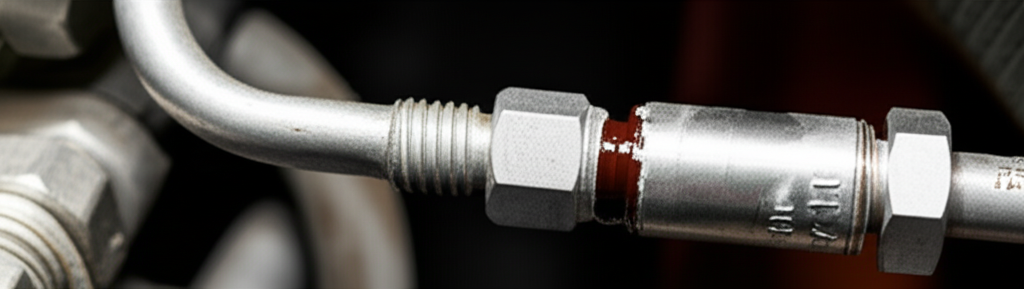

Oil Stains: Around fittings or welds on refrigeration systems, a slight oil residue can indicate where refrigerant has escaped, often allowing air to enter when the system is not running.

Pinpointing the Problem: Common Causes of Air Leaks

Understanding the common culprits behind these leaks is crucial for effective diagnosis and repair:

Loose Fittings and Connections: Over time, vibrations or improper initial tightening can cause flanges, unions, or threaded connections to loosen, creating pathways for air.

Damaged Gaskets and O-rings: These sealing components deteriorate with age, exposure to chemicals, or extreme temperatures, losing their elasticity and sealing capability.

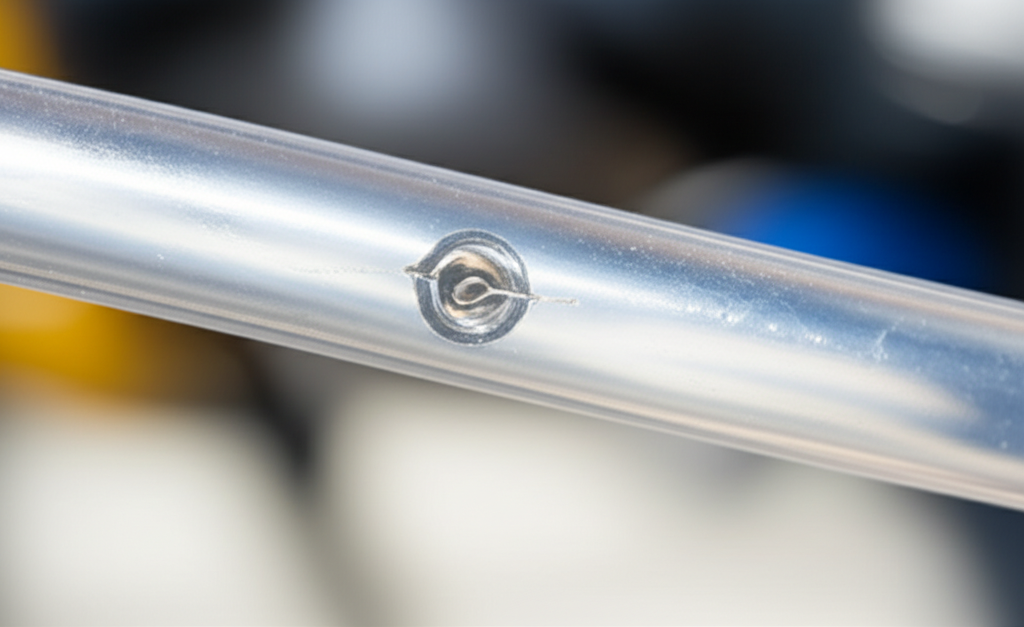

Cracks or Pinholes in Piping: Corrosion, physical impact, material fatigue, or manufacturing defects can lead to hairline cracks or pinholes in the suction line piping.

Poor Brazing or Soldering: In refrigeration systems, improperly brazed joints are common points of failure, initially leaking refrigerant, and then allowing air entry.

Mechanical Damage: Accidental impacts during installation, maintenance, or operation can physically damage the line.

Wear and Tear: Components like valve stems, pump seals, or connection points are subject to wear over their operational lifespan.

Diagnostic Dilemma: How to Detect an Air Leak in Your Suction Line

Detecting a hard-to-find air leak in suction line requires a systematic approach and, sometimes, specialized tools.

1. Visual Inspection: Start by thoroughly inspecting all accessible parts of the suction line. Look for:

Oil stains (especially on refrigeration lines).

Visible cracks, damage, or discolouration on pipes.

Loose or corroded fittings.

Condensation or frost patterns that seem unusual (e.g., uneven frosting on a refrigeration suction line).

2. Soap Bubble Test: For systems that can hold positive pressure (even briefly), this classic method is highly effective for smaller leaks. Apply a solution of dish soap and water to suspected areas (fittings, welds, valves). Air escaping will create visible bubbles. Caution: Only apply soap solution when the system isn’t running or under safe, controlled conditions, especially with electrical components.

3. Electronic Leak Detectors: For refrigerant systems, electronic leak detectors are invaluable. These devices can sniff out the presence of specific refrigerant gases escaping minute cracks, indirectly indicating where air might also enter when the system is off or under vacuum.

4. Vacuum or Pressure Decay Test: This method is more advanced. The system is either pulled into a deep vacuum or pressurized with an inert gas (like nitrogen, NEVER oxygen or air for refrigeration). The system is then isolated, and a gauge monitors the pressure or vacuum over a period. A loss in vacuum or pressure indicates a leak.

5. Listening: A keen ear can sometimes pinpoint a faint hissing sound of air being drawn into the system, especially if the leak is substantial.

The Crucial Fix: Solving the Air Leak Problem

Once located, fixing an air leak swiftly is essential to restore system integrity and performance. The “crucial fix” largely depends on the nature and location of the leak:

1. Tighten Connections: The simplest fix. If a fitting, valve, or union is loose, carefully tightening it to the manufacturer’s specifications can often resolve the issue. Avoid over-tightening, which can strip threads or damage components.

2. Replace Damaged Gaskets and O-Rings: If a seal is compromised, simply replacing it with a new, compatible one is often the solution. Ensure proper seating and lubrication (if required) for optimal sealing.

3. Repair or Replace Piping:

Minor Cracks/Pinholes: Depending on the material and system, small leaks in pipes might be repaired via welding (for metal pipes) or with specialized pipe repair clamps.

Damaged Sections: For more extensive damage, cutting out the faulty section and replacing it with a new piece of pipe, properly joined (brazed, welded, or mechanically coupled), is necessary.

4. Re-Brazing or Re-Soldering: In refrigeration/HVAC, if a brazed joint is found to be leaking, the old braze material must be carefully removed, the area cleaned, and a new, professionally executed braze joint created. Proper techniques, including nitrogen purging during brazing, are vital to prevent internal oxidation.

5. Post-Repair Evacuation and Recharging/Repriming: After any repair on a suction line, especially in closed-loop systems like refrigeration, it’s crucial to evacuate the system to remove any introduced air and moisture. This ensures the system is free of non-condensable gases before refilling with the appropriate fluid (refrigerant, water, hydraulic fluid). For pumps, repriming the line is necessary.

Why Professional Intervention Matters

While some minor fixes can be DIY, an air leak in suction line, particularly in complex systems involving refrigerants or high pressures, often necessitates professional expertise. Technicians possess the specialized tools (vacuum pumps, manifold gauges, leak detectors), knowledge of system specifics, and safety training required to diagnose accurately and perform lasting repairs. Furthermore, handling refrigerants is ecologically sensitive and often regulated, requiring licensed professionals.

Conclusion

An air leak in a suction line is far more than a minor inconvenience; it’s a silent threat to the efficiency, longevity, and operational integrity of countless mechanical systems. From the subtle hum of a struggling compressor to the complete failure of a water pump, the symptoms are varied but the underlying cause is consistently debilitating. Prompt and precise diagnosis, followed by the crucial and correct fix, is not just about restoring functionality but about preserving the lifespan of valuable equipment, optimizing energy consumption, and ensuring the safety and reliability of operations. Don’t let an air leak compromise your system’s integrity; addressing it promptly is a smart investment in sustained performance.