Variable Speed Pump technology represents a seismic shift in how fluid systems operate, moving away from constant brute force to intelligent, demand-driven performance. For decades, traditional fixed-speed pumps have been the workhorses of countless industries and homes, often operating at full capacity regardless of actual need. This “all or nothing” approach has led to tremendous energy waste, higher operational costs, and unnecessary wear and tear on equipment. However, with the advent and widespread adoption of variable speed drives, pumps can now precisely match their output to real-time system demands, leading to truly transformative energy savings and superior system control.

Traditional pumps, also known as fixed-speed or single-speed pumps, are designed to operate at a constant rotational speed, typically determined by their motor’s electrical supply. When the system requires less flow or pressure than the pump is capable of producing at full throttle, operators often resort to mechanical throttling using valves, or bypass systems. While these methods achieve the desired flow reduction, they do so inefficiently. Imagine driving a car with the accelerator pressed to the floor, and using the brakes to control your speed. That’s essentially what a throttled fixed-speed pump does – it expends full energy to move fluid, then dissipates the excess energy as heat and pressure loss through the constriction of a valve. This wasted energy translates directly into higher electricity bills and a larger carbon footprint.

Understanding the Energy Savings Potential of a Variable Speed Pump

The core principle behind the incredible energy savings offered by a variable speed pump lies in the “affinity laws” of fluid dynamics. These laws describe the relationship between a pump’s speed, flow rate, head (pressure), and power consumption. Specifically, the most impactful one states that the power absorbed by a pump is proportional to the cube of its speed.

What does this mean in practical terms? It means that even a small reduction in pump speed can lead to a drastic reduction in energy consumption:

Reducing pump speed by just 10% can lower power consumption by approximately 27%.

Reducing pump speed by 20% can lower power consumption by approximately 49%.

Cutting the pump speed in half (50%) can reduce power requirements by a staggering 87.5% (0.5 x 0.5 x 0.5 = 0.125, meaning only 12.5% of the original power is needed).

This exponential relationship is why investing in a variable speed pump is not just about incremental improvements, but about unlocking truly substantial energy efficiencies, often resulting in payback periods of just a few years or even months.

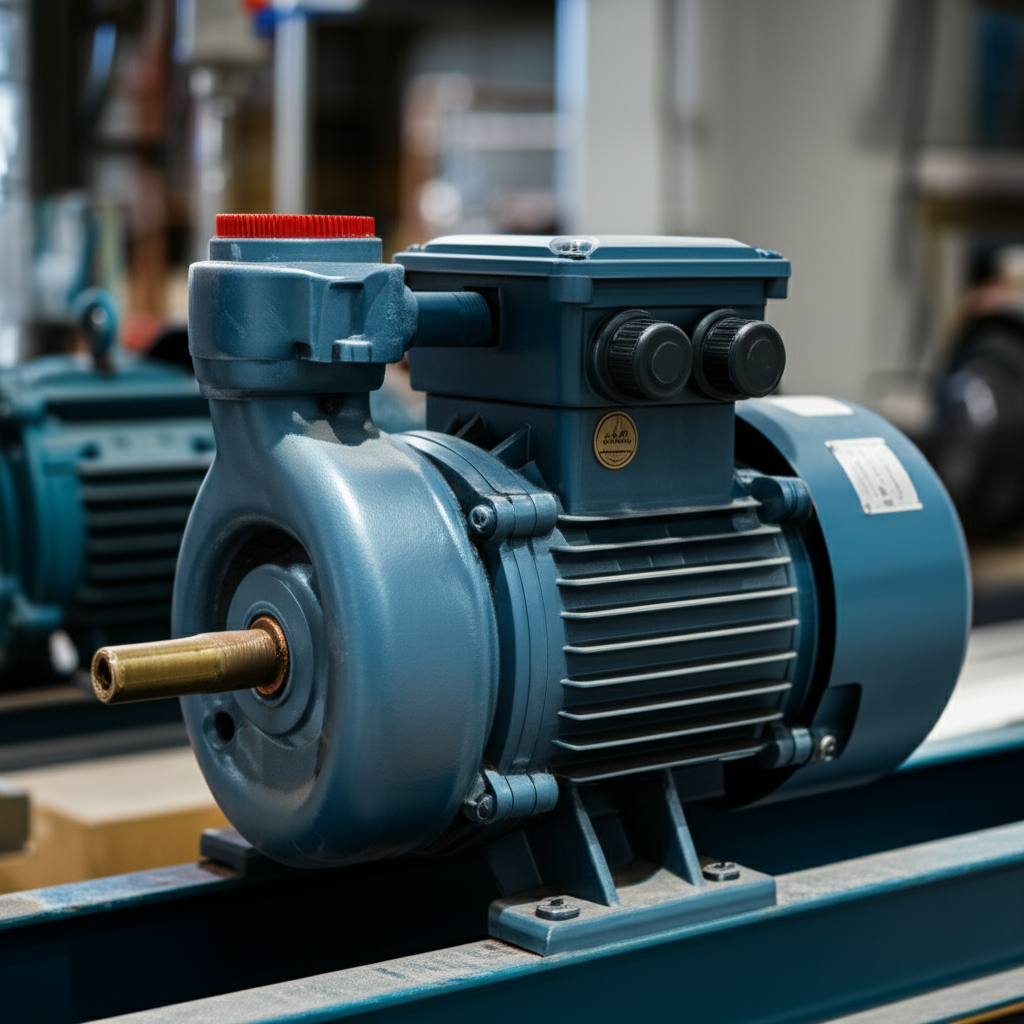

A variable speed pump system comprises a standard pump, an electric motor, and a variable frequency drive (VFD) or variable speed drive (VSD). The VFD is the brains of the operation, converting the fixed-frequency and fixed-voltage input power from the grid into variable-frequency and variable-voltage output power. This allows the VFD to precisely control the motor’s rotational speed, and consequently, the pump’s output, based on real-time feedback from pressure sensors, flow meters, or temperature sensors within the system.

Beyond Just Energy Savings: The Multifaceted Benefits

While vast energy reduction is the primary driver for adopting variable speed pump technology, the benefits extend far beyond the utility bill:

Improved System Control and Stability: By precisely matching output to demand, VSPs maintain more consistent pressures, temperatures, or flow rates, leading to more stable and optimized industrial processes, HVAC systems, or domestic water supply.

Reduced Wear and Tear & Extended Equipment Life: Fixed-speed pumps often experience harsh starts (full power instantly) and operate under constant stress. VSPs, on the other hand, provide soft starts, gradually ramping up to speed, and operate at lower average speeds. This significantly reduces mechanical stress on the pump, motor, piping, and other system components, leading to fewer breakdowns, lower maintenance costs, and a longer operational lifespan for the entire system.

Lower Noise and Vibration: Operating at lower speeds often results in quieter pump operation and reduced mechanical vibration, contributing to a more comfortable and productive environment, especially in commercial and residential settings.

Enhanced Reliability and Diagnostics: Many modern VFDs come with built-in diagnostic capabilities that can monitor motor health, detect potential issues, and even communicate with building management systems for proactive maintenance.

Environmental Impact: Lower energy consumption directly translates to a reduced carbon footprint, contributing to sustainability goals and compliance with environmental regulations.

Diverse Applications for Variable Speed Pumps

The versatility of variable speed pump technology makes it suitable for a wide array of applications across various sectors:

HVAC Systems: Chilled water, condenser water, and hot water circulation in commercial buildings benefit immensely from VSPs, adjusting flow rates based on building occupancy and external temperatures.

Industrial Processes: Chemical processing, food and beverage production, pharmaceutical manufacturing, and water treatment plants often require precise flow and pressure control, making VSPs indispensable for efficiency and product quality.

Water and Wastewater Management: Pumping stations, booster pumps, and wastewater treatment aeration systems utilize VSPs to handle fluctuating demands, optimize operations, and conserve energy.

Commercial and Residential Swimming Pools: A variable speed pump for a swimming pool can dramatically cut electricity costs (often the biggest expense for pool owners) by running the pump at lower speeds for filtration and higher speeds only when needed for cleaning or special features.

Agriculture and Irrigation: Matching pump output to real-time irrigation needs or varying crop demands helps conserve water and energy.

Oil and Gas: Downstream and midstream operations benefit from VSP control for various fluid transfer tasks.

The choice to implement variable speed pump technology is a strategic investment that pays dividends in multiple ways. By understanding the underlying principles and the far-reaching benefits, industries and homeowners alike can make informed decisions to modernize their fluid handling systems, move towards a more sustainable future, and unlock truly enormous energy savings. The era of the “one-speed-fits-all” pump is rapidly fading, replaced by intelligent, adaptable, and incredibly efficient variable speed solutions.