- The Challenges of Manual Chemical Addition

- Understanding the Automatic Chemical Doser

- Unpacking the Benefits: Why Automation is Superior

- Applications Across Diverse Industries

- Choosing the Right Chemical Feeder System

- The Future of Precision Dosing: Advanced Automatic Chemical Doser Systems

An Automatic Chemical Doser stands as the ultimate, easy solution for industries and applications requiring precise and consistent chemical addition. In countless processes, from water treatment facilities to manufacturing plants, the accurate introduction of chemicals is not just a recommendation but a critical necessity for operational efficiency, product quality, and safety. Manual dosing, while seemingly straightforward, is fraught with inconsistencies, safety hazards, and labor-intensive demands. This is where automated systems step in, transforming complex chemical management into a streamlined, reliable, and highly effective operation.

The Challenges of Manual Chemical Addition

Historically, many operations relied on manual methods for adding chemicals, often involving personnel measuring and pouring substances into tanks or systems. This approach presents a multitude of challenges:

Inaccuracy and Inconsistency: Human error is inevitable. Slight deviations in measurement or timing can lead to over or under-dosing, impacting product quality, system performance, or environmental compliance.

Safety Risks: Handling concentrated chemicals manually exposes workers to potential spills, splashes, and inhalation hazards, requiring extensive personal protective equipment and training.

High Labor Costs: Dedicating staff to repetitive manual dosing tasks diverts valuable resources from other critical operations.

Waste and Inefficiency: Incorrect dosing often results in wasted chemicals or the need for costly rework, translating directly to higher operational expenses.

Lack of Control: Manual systems offer minimal real-time control or adjustment capabilities, making it difficult to respond quickly to changing process conditions.

These inherent drawbacks underline the pressing need for a more sophisticated and reliable approach to chemical management.

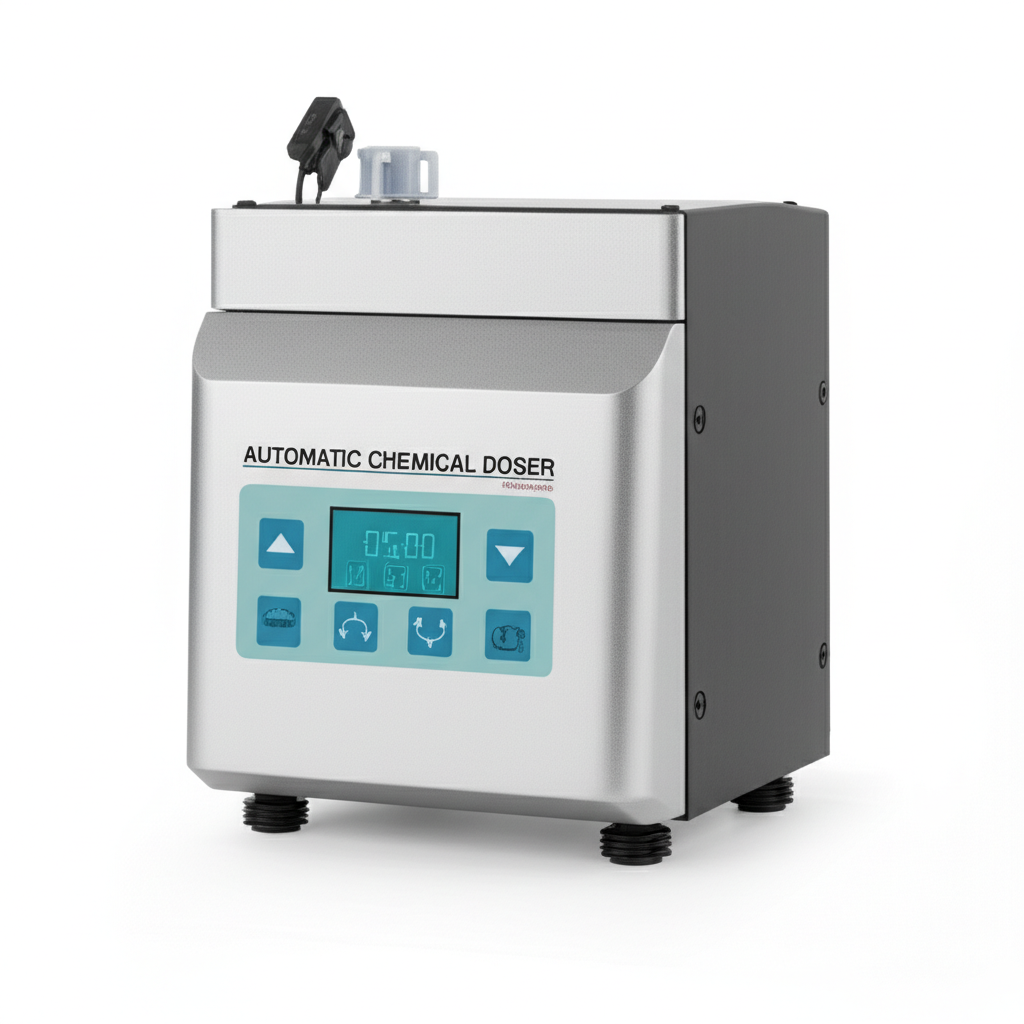

Understanding the Automatic Chemical Doser

At its core, an automatic chemical doser, often referred to as a Chemical Feeder, is a system designed to add specific quantities of a chemical into a process stream at predetermined intervals or in response to real-time process parameters. The heart of many of these systems is a Dosing Pump, a precise positive displacement pump capable of delivering very accurate volumes of fluid.

These systems consist of:

Chemical Storage: A tank or container for the chemical concentrate.

Dosing Pump: To draw and inject the chemical.

Control System: This can range from simple timers to sophisticated programmable logic controllers (PLCs) or even Internet of Things (IoT) integrated systems, often linked to sensors.

Injection Point: A mechanism (like an injection quill) to introduce the chemical safely into the main process line.

The versatility of an automatic chemical doser allows for various control modes, including continuous dosing at a fixed rate, proportional dosing (where the chemical addition rate adjusts based on the flow rate of the main process), or feedback control (where sensors like pH, ORP, or conductivity meters dictate the dosing activity).

Unpacking the Benefits: Why Automation is Superior

The adoption of an automatic chemical doser brings a wealth of advantages that significantly outweigh initial investment costs:

Unparalleled Precision and Accuracy: Automation eliminates human error, ensuring chemicals are added in precisely the right amounts, every time. This optimizes chemical consumption and process outcomes.

Enhanced Safety: By minimizing direct human contact with hazardous chemicals, automatic systems drastically reduce the risk of accidents, contributing to a safer work environment and potentially lowering insurance costs.

Significant Cost Savings: Precision dosing reduces chemical waste, leading to substantial savings on chemical purchases. Furthermore, reduced reliance on manual labor frees up personnel for higher-value tasks, cutting labor expenses.

Consistent Performance: Automated systems operate tirelessly and consistently, maintaining optimal conditions around the clock. This translates to stable process performance, consistent product quality, and reliable compliance.

Improved System Efficiency and Compliance: Maintaining tight control over chemical concentrations helps prevent scaling, corrosion, bacterial growth, and other issues that can degrade equipment or lead to regulatory non-compliance.

Real-time Monitoring and Control: Many advanced dosers offer integration with sensors and SCADA systems, providing real-time data and allowing for immediate adjustments, remote monitoring, and comprehensive data logging for analysis and reporting.

Applications Across Diverse Industries

The utility of chemical feeders extends across a vast spectrum of industries:

Water Treatment: Essential for municipal water purification (chlorination, fluoridation), wastewater treatment (coagulation, pH adjustment), swimming pools (sanitizers, pH balancers), and cooling towers (biocides, scale inhibitors).

Agriculture: Used for precise nutrient injection (fertigation), pH adjustment in hydroponic systems, and pathogen control.

Food and Beverage: Critical for sanitization, washdown processes, and pH control in various production stages.

Manufacturing: From metal finishing and plating to textile processing, chemical dosers ensure consistent chemical baths and treatments.

HVAC Systems: For chemical treatment of boiler water and closed-loop heating/cooling systems to prevent corrosion and scale.

Wherever a chemical needs to be added precisely, safely, and consistently, an automatic chemical doser provides an indispensable solution.

Choosing the Right Chemical Feeder System

Selecting the appropriate automatic chemical doser involves considering several factors:

Chemical Compatibility: The materials of construction for the dosing pump and associated components must be compatible with the chemical being dosed to prevent corrosion or degradation.

Flow Rate and Pressure: The dosing pump must be capable of delivering the required flow rate against the operating pressure of the process line.

Control Requirements: Determine if a simple timer, proportional control, or a sophisticated sensor-driven feedback loop is needed.

Accuracy and Turndown Ratio: Consider the level of precision required and the pump’s ability to maintain accuracy over a wide range of flow rates.

Installation Environment: Environmental factors like temperature, humidity, and ventilation can influence material choices and system design.

Maintenance and Serviceability: Opt for systems known for reliability and ease of maintenance to minimize downtime.

Investing in a well-matched automatic chemical doser ensures long-term operational success and maximizes the benefits of automation.

The Future of Precision Dosing: Advanced Automatic Chemical Doser Systems

The evolution of automatic chemical dosers continues, driven by advancements in technology. Future systems are increasingly integrated with smart technologies, offering:

IoT Connectivity: Enabling remote monitoring, control, and predictive maintenance through cloud-based platforms.

AI and Machine Learning: To optimize dosing strategies based on historical data and real-time fluctuations, leading to even greater efficiency and chemical savings.

* Enhanced Diagnostics: Providing proactive alerts and fault detection to prevent system failures before they occur.

These innovations promise even more efficient, reliable, and user-friendly chemical management solutions, further cementing the status of the automatic chemical doser as an indispensable tool.

In conclusion, the automatic chemical doser truly represents the ultimate, easy solution for modern chemical management. By providing unparalleled precision, enhancing safety, reducing operational costs, and ensuring consistent performance, these systems empower industries to operate more efficiently, compliantly, and sustainably. Transitioning from manual to automated chemical dosing is not just an upgrade; it’s a strategic imperative for any operation serious about optimizing its chemical processes.